Feller-Buncher Operator Falls From Loader

BACKGROUND: On a clear, spring afternoon in the South, a feller-buncher operator was assisting another employee with the in-woods replacement of a windshield on the knuckleboom loader.

BACKGROUND: On a clear, spring afternoon in the South, a feller-buncher operator was assisting another employee with the in-woods replacement of a windshield on the knuckleboom loader.

PERSONAL CHARACTERISTICS: The 30-year-old operator was fully qualified as a feller-buncher operator. He had only been employed for one month with this crew but had several years of experience on other logging jobs. He was wearing the required Personal Protective Equipment for the job.

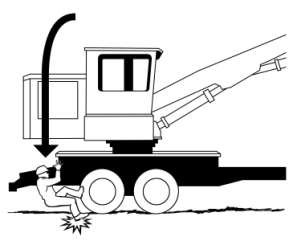

UNSAFE ACTS AND CONDITIONS: Two employees finished the windshield repair and prepared to step down from the loader. The feller-buncher operator, who had (unsafely) positioned himself on the top of the loader’s cab during the repair, was not on the loader platform and was not using an acceptable fall-prevention practice or device. Additionally, in climbing down from the top of the cab onto the engine compartment, he failed to use three points of contact (that is, to have a combination of two hands and one foot or two feet and one hand always in contact with steps, handrails, or other stable surface).

ACCIDENT: As the feller-buncher operator stepped down onto the engine compartment of the loader, he lost his footing. He fell off the loader and landed on his right heel.

INJURY: The impact caused a fracture to his right heel. He underwent outpatient surgery and was expected to be out of work for 6 to 8 weeks.

RECOMMENDATIONS FOR CORRECTION:

- Equipment manufacturers recommend that the loader be parked on level ground with the grapple lowered to the ground, and the front window accessed and replaced from the position of the subframe platform, not from the top of the cab.

- Other safety-focused alternatives would have been for the feller-buncher operator to use a firmly supported ladder for this procedure, or to replace the window in the shop or with the aid of equipment where better safety controls (such as a fall arrest system, scaffolding, or hydraulic lift) are in place for working on elevated machine components.

- All employees must use three points of contact at all times when entering, exiting, or climbing onto or off of vehicles and equipment.

- Slip-resistant work boots, free of mud and debris, are recommended to prevent slips.

- Logging injuries can be prevented with proper training and commitment to following safety procedures and “not to be in a hurry.”

Courtesy of the Forest Resources Association: forestresources.org

Latest News

NC To Offer First High School Forestry Course in 2024-25

The North Carolina Forestry Assn. (NCFA) has teamed up with the North Carolina Future Farmers of America Assn. (NC FFA) to create North Carolina’s first-ever high school forestry course with an industry-aligned credential: AN53 Natural Resources...

Enviva Proceeds Into Chapter 11

Enviva Inc., the world’s largest producer of industrial wood pellets, and certain of its subsidiaries have commenced voluntary Chapter 11 proceedings in the U.S. Bankruptcy Court for the Eastern District of Virginia, citing $1.8 billion of debt outstanding.

Have A Question?

Send Us A Message